What can stop the Auto rally?

Analysing impact of possible semiconductor shortage

We hope you had a great Diwali!

But Diwali of 2021 was not good for auto dealers. They had customers in their showrooms but no cars to sell. With a huge order backlog & ever-increasing delays in delivery, customers were canceling their orders out of disappointment.

The culprits were the semiconductors. Shortage of semiconductors forced several automakers to halt production worldwide.

Semiconductors, usually called chips, are critical components that power electronics from computers and smartphones to the brake sensors in cars. The production of chips involves a complex network of firms that design or make them, as well as, those that supply the technology, materials, and machinery to do so. India significantly lags in the production of chips.

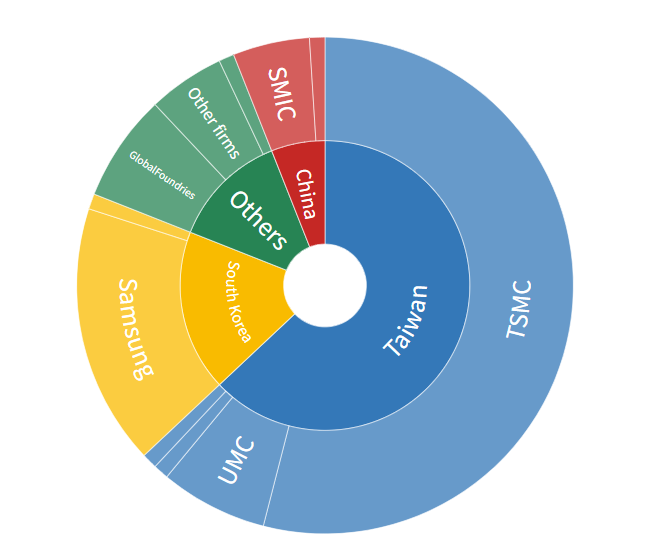

As shown in this breakup below (Trendshare 2021):

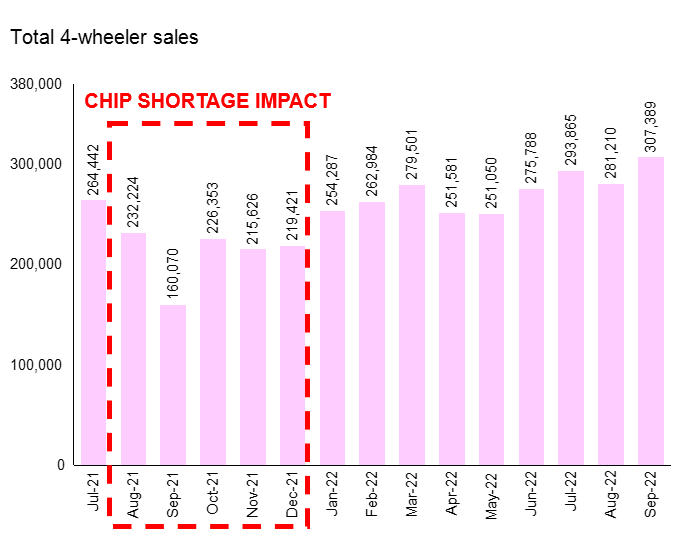

Over 80% of the chips come from Taiwan & South Korea. India imports most of its chips required with no production facility available onshore. Because of the unavailability of chips, autos saw a negative growth Y-o-Y in several key months post-monsoon. The graph here shows the 4-wheeler sales in the months of 2021 & 2022:

August to December months of 2021 were actually one of the worst months in the past several years. As an effect, many auto manufacturers reported over 100% y-o-y growth in recent months, the key reason being the low base effect.

Where the companies sold over 300K+ cars in September of 2022, they could only sell ~160K same month last year. Here’s a list of the impact of chip shortage over Autos:

Declining Revenue: As discussed above, when you have no cars to sell in your showroom, you witness a sharp fall in revenues.

Emphasis on lower tech vehicles: The more features in a car, the more the requirement of chips in it. The lack of chips promotes the production of cars with lesser features in them, significantly affecting the production of premium/car models with better features (read low margins).

Product Redesigns: This is an impactful structural decision to be taken by automakers but can be costly & time-consuming as well. Volkswagen mentioned looking at modules with lesser chips in their last year in their last year’s investor calls.

Remember, there still exists an order backlog of 8.25 lakh of the whole industry, with Maruti’s share at 4.40 lakh alone.

Hoping any supply shortage doesn’t occur, but if it does, you now know what to do :)

See you in the next post!